Home /Laboratory Balance

Laboratory Balance

Pruiste is a laboratory balance factory in china, laboratory balance is an indispensable precision instrument in modern scientific research and industrial quality control, used as a tool for measuring the mass of substances. Unlike ordinary scales, laboratory scales can provide extremely high accuracy and precision, typically measuring levels of micrograms (μ g) or even nanograms (ng). This type of instrument is widely used in various fields such as chemistry, biology, pharmaceuticals, food science, and materials research, and is the fundamental equipment for quantitative analysis.

The core value of laboratory balance lies in their ability to provide reliable and reproducible measurement results, which is crucial for the scientific validity of experimental data and the credibility of research results. Accurate quality measurement is a key factor in ensuring the success of experiments, whether it is preparing standard solutions, weighing reactants, measuring sample weight, or conducting quality control.

The main types of laboratory balance

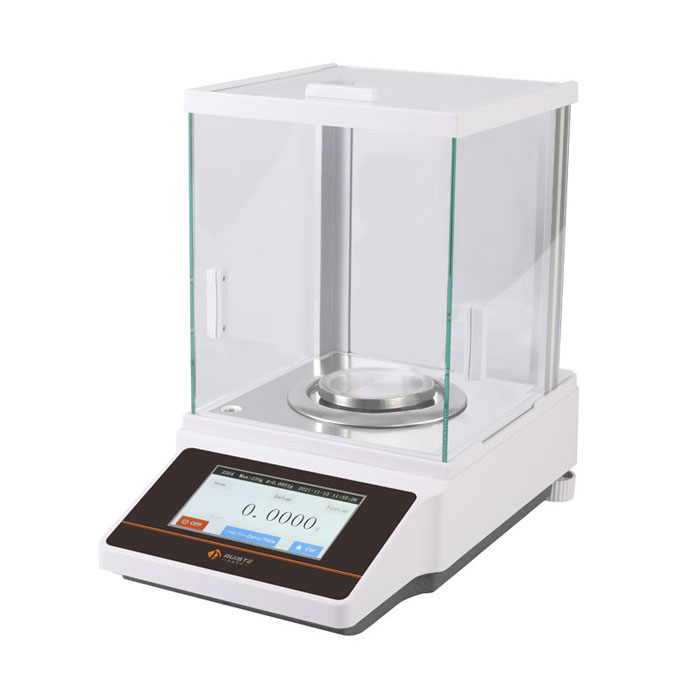

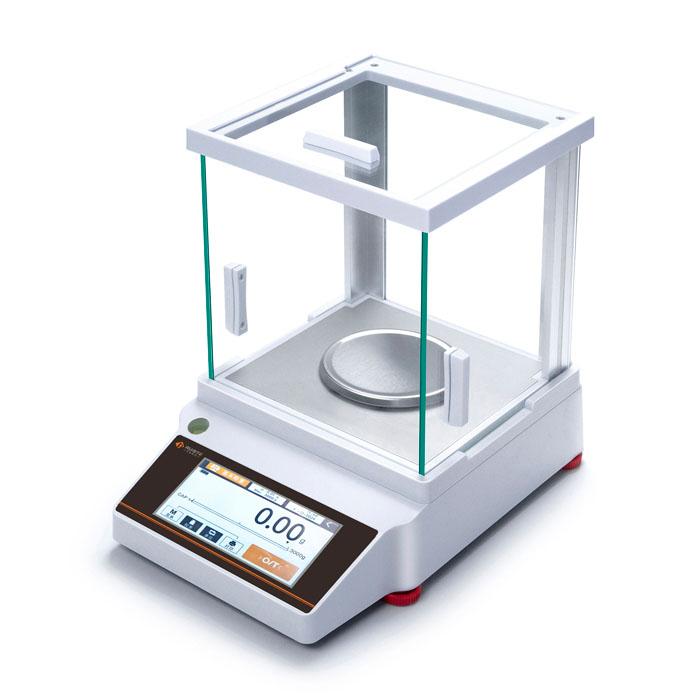

- Analytical balance

Analytical balance is one of the most precise weighing instruments in the laboratory, typically with a resolution of 0.1mg (0.0001g) or higher. This type of balance adopts the principle of electromagnetic force balance, which balances the weight of the object being weighed by the force generated by the electromagnetic coil, thereby measuring mass. Modern analytical scales are typically equipped with windproof covers (dust covers) to reduce the impact of air flow on the symmetry results, and have built-in calibration weights for automatic calibration. - Precision balance

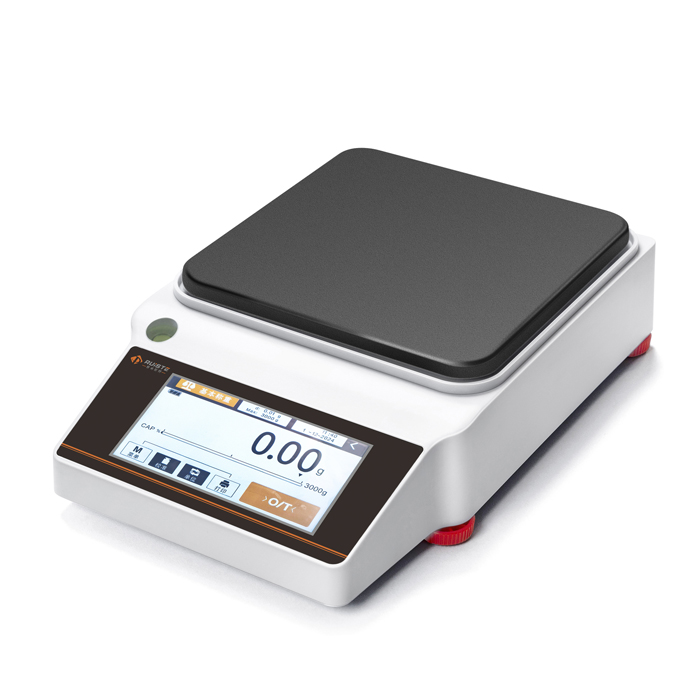

The resolution of a precision balance is usually between 0.01g and 0.001g, which is suitable for situations that require high accuracy but do not have to meet analytical grade requirements. This type of balance has a relatively simple structure and low price, and is commonly used in teaching laboratories or daily quality control. Precision scales usually use strain gauges or electromagnetic force compensation technology, which have good stability and durability. - Microbalance

A microbalance is an ultra high precision instrument specifically designed for measuring extremely small masses (usually less than 1g), with a resolution of up to 0.1 μ g or even higher. This type of balance is extremely sensitive to environmental impact and must be installed on a specialized seismic platform and used under strictly controlled environmental conditions. Microbalance is commonly used in fields such as drug development, nanomaterial research, and trace analysis. - Moisture determination balance

The moisture determination balance (halogen moisture analyzer) is a specialized balance that integrates weighing and heating functions. It measures the moisture content in a sample by heating it and continuously weighing it. This type of balance is widely used in quality control processes in industries such as food, pharmaceuticals, and chemicals, and can quickly and accurately determine the moisture content in solid or semi-solid samples.

Key technical parameters of laboratory balance

- Range and Resolution

Range refers to the maximum mass value that the balance can measure, while resolution is the minimum mass change that the balance can display. There is a trade-off between these two - the higher the resolution, the smaller the range usually. When choosing a balance, these two parameters should be balanced according to the actual application needs. - Readability

Readability refers to the minimum unit that a balance display screen can display, usually expressed in decimal places. For example, 0.0001g indicates that the balance can display up to four decimal places, which is the 0.1mg level. - Repeatability

Repeatability refers to the degree of similarity in the results of weighing the same object multiple times under the same conditions, and is an important indicator for measuring the precision of a balance. Good repeatability means stable and reliable measurement results. - Linear error

Linear error represents the variation of measurement error of the balance at different range points. In an ideal situation, the error of the balance should remain consistent throughout the entire range. High precision scales typically have very small linear errors. - Stable time

The stabilization time refers to the time required from placing the sample to displaying a stable reading. Modern electronic scales typically have a fast stabilization function that can provide stable readings within seconds.

The core components of laboratory balance

- Weighing sensor

The weighing sensor is the core component of the balance, responsible for converting mass into electrical signals. Common types of sensors include electromagnetic force compensation sensors, strain gauge sensors, and capacitive sensors. Among them, the electromagnetic force compensation sensor has the highest accuracy and is widely used in analytical scales. - Windproof system

Precision scales are usually equipped with transparent windproof covers to reduce the impact of air flow on the symmetry results. Advanced scales may also have automatic opening and closing of wind doors and optimized airflow design. - Calibration system

Modern laboratory balance typically have built-in calibration weights and automatic calibration functions, allowing for regular or on-demand internal calibration to ensure measurement accuracy. Some high-end models also support external weight calibration and adjustment. - Display and operation interface

The operation interface of the balance includes a display screen and buttons (or touch screen), which are used to display measurement results and make various settings. Modern scales typically have large LCD displays that can display multiple parameters and status information. - Data interface

Most laboratory balance are equipped with data interfaces such as RS-232, USB, or Bluetooth, which can transmit weighing data to computers or printers. Some models also support network connectivity and remote monitoring functions.

The working principle of laboratory balance

- Modern electronic laboratory balance mainly work based on the principle of electromagnetic force balance. When an object is placed on a weighing plate, its gravity will cause displacement or deformation of the sensor. The sensor detects this change and converts it into an electrical signal, and the control system then generates an opposite electromagnetic force to balance the object's gravity. By measuring the current required to maintain balance, the mass of an object can be calculated.

- This process is achieved through a precise closed-loop feedback system, which has the characteristics of fast response and high accuracy. The balance also includes a temperature compensation circuit inside, which can reduce the impact of environmental temperature changes on the measurement results. Advanced digital filtering algorithms are used to eliminate noise caused by vibrations and other interferences, ensuring stable readings.

The use and maintenance of laboratory balance

- Correct usage process

Ensure that the balance is placed on a stable and level surface, away from sources of vibration and airflow

Preheat for at least 30 minutes before use (high-precision scales may require longer time)

Regularly calibrate, especially when there are significant changes in ambient temperature or when the balance is moved

Close the windproof door during weighing and record the reading after the display stabilizes

Avoid exceeding the maximum range of the balance to prevent damage to the sensor - Key points of daily maintenance

Keep the weighing room clean and regularly use a soft brush or balloon to remove dust

Avoid direct contact of corrosive substances with the weighing plate, and use weighing containers if necessary

When not in use, the power should be turned off, and if not used for a long time, the battery (if any) should be removed

Regularly check the level status to ensure that the bubble level is in the center position

Perform professional maintenance and periodic verification according to the manufacturer's recommendations - Common problem troubleshooting

Unstable reading: Check for airflow, vibration, or static interference to ensure the balance is securely placed

Display error code: Refer to the user manual for specific meaning, contact technical support if necessary

Calibration failed: Confirm stable environmental conditions and check if the built-in weights are clean and undamaged

Zero drift: may require recalibration or professional repair due to temperature changes or sensor issues

Guidelines for selecting laboratory balance

- Choose according to application requirements

Conventional laboratory work: Select an analytical balance with a resolution of 0.1mg

Microanalysis: Consider using a microbalance with a resolution of 1 μ g or higher

Industrial quality control: may require more robust and durable precision scales

On site testing: Consider portable scales or models with battery powered functionality - Consider the work environment

Environment with vibration or airflow: choose a balance with good stability and windproof system

Corrosive environment: Choose models with anti-corrosion coatings

Cleanroom application: Consider using specialized scales that comply with relevant cleanliness standards - Functionality and Scalability

Data recording requirements: Choose a balance with complete data interfaces and software support

Special application: Consider a balance with additional functions such as density measurement and statistical calculation

Future expansion: Choose modular design, models that can add accessories and upgrade software - Budget and Brand

Set a reasonable budget and balance initial costs with long-term use value

Consider the product quality and after-sales service guarantee of well-known brands

Assess the overall cost of ownership, including maintenance, calibration, and consumables expenses

The importance of laboratory balance in scientific research

The laboratory balance as a fundamental but crucial research tool, plays an irreplaceable role in promoting scientific progress. Accurate weighing is the basis for determining formulation and dosage in drug development; In materials science, nanoscale weighing technology provides support for the development of new materials; In environmental monitoring, high-sensitivity balance enables the detection of trace pollutants.

With the advancement of technology, laboratory balance have evolved from simple weighing tools to intelligent systems that integrate measurement, calculation, data management, and process control. They are not only the source of experimental data, but also an important guarantee for scientific rigor and reproducibility. In modern laboratories, selecting, using, and maintaining balance equipment is one of the key factors in ensuring the quality and efficiency of scientific research.

In the future, with the rapid development of nanotechnology, biotechnology, and artificial intelligence, laboratory balance will continue to evolve, providing scientists with more accurate, intelligent, and integrated measurement solutions, and helping humanity explore unknown scientific frontiers.

CopyRight © 2025 Pruiste(An Hui) Measuring Technology Co.,Ltd. All Rights Reserved. Sitemap

Chinese Mobile

Chinese Mobile Whatsapp Service

Whatsapp Service WeChat Service

WeChat Service